Fabrication, Piping, Seafastening & Structural Solutions Malaysia

Higher Tech Engineering Sdn Bhd

About Us

Higher Tech Engineering Sdn Bhd (HTESB) was formed in 2024 by the director, Muhamad Naufal Husaini. This company operates under Higher Tech Fabricator Sdn Bhd. HTESB offers a full range of services including onshore/offshore Fabrication, Piping, Seafastening & Structural Solutions Malaysia, structural and mechanical installation, turnaround plant projects, and heavy lifting works. We ensure that your journey with us will be filled with endless possibilities.

HTESB employs highly skilled and qualified staff with wide expertise, delivering top-quality standards in steel fabrication with precision and uncompromising attention to detail. Our commitment is to deliver the best products and services, driven by a strong and dedicated team, which is the key driver of our success.

Vision

In our quest for continued success and growth, Higher Tech Engineering’s vision is to be recognized as the contractor and employer of choice. Our goal is to deliver every project to the highest standard through excellent communication and professionalism.

Mission

Our mission is to be the preferred provider for safety-first, incident-free, and reliable services across industries with high-quality solutions that meet all client requirements.

Our Expertise

Comprehensive solutions in fabrication, piping, seafastening, blasting, maintenance & offshore services across Malaysia.

Gas and Piping Line

End-to-end oil and gas pipeline solutions using advanced design, permitting, control systems & commissioning, ensuring compliance and expert execution.

Steel Structure & Installation

We deliver complex steel fabrication & installation projects with high-quality craftsmanship, meeting international standards and tight deadlines.

Steel Repair & Maintenance

Reliable repair and maintenance for oil & gas, marine & industrial steel structures, delivered by qualified technicians with proven expertise.

Ship & Rig Repair & Maintenance

ISPS-certified shipyards in Malaysia for safe, efficient, on-time vessel & offshore platform repair by skilled marine technicians.

Sea Fastening Services

Custom sea fastening design & fabrication for offshore transport, ensuring safety, compliance & structural integrity throughout voyages.

Blasting & Painting Works

Full-service blasting & coating operations using rope access, offshore safe methods, and international surface preparation standards for long-lasting corrosion protection.

Barge Handrail Works

Specialized in fabrication & installation of safety handrails for marine & offshore vessels, ensuring safe working conditions at sea.

Tank & Bundle Cleaning

Safe, efficient tank cleaning for crude oil, wastewater, chemical storage and decontamination, handled by highly-trained technicians with strict safety protocols.

Our Clients

Trusted by leading companies organizations in Malaysia's engineering, oil & gas, and marine sectors.

Projects

Our Recent Projects

ERESB/SLB RACKING PROJECT DETAILS

Racking project for Easy Region Engineering (ERESB)

- Start: 12.01.2015

- Status: Completed

MPI LOAD TEST WORKS DETAILS

Wet magnetic particle inspection uses a solution of fluorescent magnetic powder and a liquid carrier. Dry magnetic particle inspection uses a visible (or) white light and to look for defects. Wet magnetic particle inspection uses ultra-violet (UV) light to find defects.

- Start: 10.02.2013

- Status: Complete

BLASTING & PAINTING WORKS DETAILS

Blasting & painting project works takes about two month of working. Our blast chamber is a 22m long x 6m wide x 5m high and constructed with concrete walls and roof. Together with our new fully enclosed 1500m2 paint shed we can undertake the painting of virtually to this project.

- Start : 26.06.2015

- Status : Complete.

46 " PIPE LOADING TO ERESB YARD DETAILS

This project required 7 days to take 46-inch pipe to load to the Easy Region Engineering (ERESB) yard. The loading process using 8 people workers to get this project done in 7 days.

- Start : 05.06.2015

- Status : Complete.

PBJV ANCHOR BUOY REPAIRING WORKS DETAILS

This project took 7 days to transport and load the 46-inch pipe to the Easy Region Engineering (ERESB) yard. A team of 8 workers carried out the loading process to complete the project within 7 days.

Our experienced and qualified teams are able to supply and repair anchor buoy as well as provide a complete maintenance management service, for not just the anchor buoys but also the supporting equipment such as floating and subsea hoses, together with the provision and maintenance of all ancillary equipment such as hose end valves, spool pieces and chainsBarakah Offshore Petroleum Berhad (PBJV) trusted us for our expertise in this field. The works take about two month to finished.

- Start : 05.06.2015

- Status : Complete.

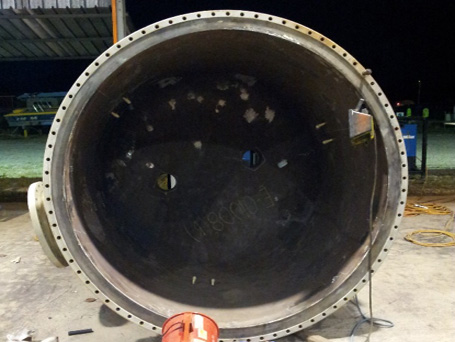

HEAT EXCHANGER HEAD REPAIRING WORKS DETAILS

We offer the most complete service of any industrial heat exchanger. This is our project in year 2015 for heat exchanger head repairing works and perform fabrication and repairs to their heat exchanger head and tube type heat exchangers, tube bundles and condensers.

- Start : 25.03.2015

- Status : Complete.

WATER PUMP FABRICATION & INSTALLATION DETAILS

The project consist of 30 people worker in total. We install vessel sea water pump for Petronas and the process takes 43 hours in total.

- Start : 10.10.2016

- Status : Complete.

CHIPPING BRUSHING & PAINTING WORKS ROV LARS DETAILS FOR TOTAL MARINE TECHNOLOGY MALAYSIA

This project involved surface preparation and protective coating works for the ROV LARS unit. Our team carried out chipping, brushing, and painting activities to restore equipment integrity, prevent corrosion, and ensure reliable offshore performance for Total Marine Technology Malaysia.

- Start :

- Status : Complete.

DOCKING ROV BRACKET & ROV PUMP BLASTING & PAINTING WORKS FOR TOTAL MARINE TECHNOLOGY MALAYSIA

This project focused on blasting and painting works for the ROV docking bracket and ROV pump system. The surface preparation and coating process were carried out to enhance corrosion resistance, extend equipment life, and ensure safe and efficient offshore operations for Total Marine Technology Malaysia.

- Start :

- Status : Complete.

HYDRAULIC HOSES REPLACEMENT WORKS FOR TOTAL MARINE TECHNOLOGY MALAYSIA

This project focused on replacing damaged and worn hydraulic hoses on critical offshore equipment. The work ensured system reliability, leak prevention, and improved safety standards. All hoses were tested and installed to meet operational requirements for Total Marine Technology Malaysia.

- Start :

- Status : Complete.

ROV BOUYANCY REPAIR FIBER & PAINTING WORKS FOR TOTAL MARINE TECHNOLOGY MALAYSIA

This project involved repairing and reinforcing the ROV buoyancy modules using high-strength fiber materials, followed by protective painting works. The repairs restored structural integrity, enhanced buoyancy performance, and provided long-term corrosion resistance for offshore operations with Total Marine Technology Malaysia.

- Start :

- Status : Complete.

FFABRICATE NEW SKID & ENCLOSHER GENERATOR SET FOR TOTAL MARINE TECHNOLOGY MARINE MALAYSIA

This project involved the design and fabrication of a new skid and “enclosher” for a generator set, tailored for offshore durability and ease of maintenance. Scope covered structural fabrication, mounting points, vibration isolation, cable routing, and protective coating—followed by alignment, functional checks, and final QA to meet TMT Marine Malaysia’s operational standards.

- Start :

- Status : Complete.

GREASING WORKS T30 WINCH FOR TOTAL MARINE TECHNOLOGY MALAYSIA

This project focused on preventive maintenance of the T30 winch system through detailed greasing works. Our team ensured all moving parts, bearings, and critical load-handling components were properly lubricated to reduce friction, prevent wear, and extend the service life of the equipment. The works were carried out following TMT Malaysia’s offshore safety and reliability standards..

- Start :

- Status : Complete.

DRUM LINER BLASTING & PAINTING WORKS DETAILS

This project based on Sabah Labuan Petronas offshore. Fabrication works for drum liner. Blasting and painting works took about two weeks to complete.

- Start : 10.03.2015

- Status : Complete.